Multi-duty mixer or Universal Mixer AnyMixing Task requiring Flow or Shear Any Unit Process or Any Unit Operation From violent Dispersions to gentle Crystallisation All in same Reactor 15. Agitator Design - Mechanical Motor Gearbox Seal Shaft 14. K.N3.D5 Low Power = Lower Cost ? High Power = Higher Energy dissipated Speed variation with constant Power VFD and Power 13. N.D High for Processes needing high Shear Low for Processes need low Shear Small diameter = Higher speed Larger diameter = Lower 12.

Diameter D/T SingleImpeller v/s Multi Impeller Bottom Clearance Impeller Spacing 11. Impellers with combined Flow and Shear UDIF or InterMig Multi Stage Large D/T Flow and 10. High Shear Impellers High Shear CowlesHigh Shear Stator-RotorGas Induction DisperserParabolic Disc 9. Axial Flow Hydrofoils High Discharge HydrofoilHigh Suction HydrofoilHigh Pitch HydrofoilHigh Solidity Hydrofoil 8. Type Selection OW LLOW F LLF A IA X AX I AOW LLOW F LLF IA A D AD I RA RFlow (Axial) Hydrofoil Axial Flow Turbine Helical PropellerShear (Radial) Cowles Rushton Turbine Stator Rotor Parabolic Disc TurbineSuspension Homogenisation Heat TransferDispersion Physical DutyLiq-Liq & Liq-Sol Reaction Dissolution Process Duty Blending Liq-Liq & Liq-Gas-Sol Reaction Emulsification 7. Agitator Selection & Design Process Impeller Type Impeller Diameter Impeller Speed Mechanical Power 6. Two Types Single MultiDuty AgitatorDuty 5. Lecture Flow Singleduty Agitator Multi duty Agitator Films showing some Interesting Mixing 4. The Mixing arena is the Boxing ring where Chemist and Chemical Engineer fight In the work done for synthesising a Chemical molecule, what % is the mass transfer, reaction and mixing and what % is separation Mixing can be demystified 3. Theres many a slip between the Plant and the Lab. Agitator Design and Selection Standard Food for Thought You wanted to STIR THINGS UP But, your MIXING gave only AGITATION. Medium and high viscosity blending, high concentration solids suspension, light duty gas dispersion. In addition, the Hydrofoil impeller can be used in three phase, solid-liquid-gas, mineral applications where relatively low gassing duty and relatively high solids concentration are present. However, the wider blades and slightly higher power number compared to the LSV also permit it to operate in low viscosity shear thinning slurries and fluids.įor operation in gas dispersion applications utilizing up-pumping configurations, the MHS serves as a secondary dispersing/blending impeller to compliment the lower primary gas dispersing impeller in high gas load applications such as fermenters. The MHS Hydrofoil agitator impeller shares efficiency benefits with the LSV in terms of hydraulic efficiency, low power number, and solid suspension performance when compared to a Pitched Blade Turbine (PBT).

The MHShydrofoil agitator impeller should be implemented in solids suspension applications when the solids concentration reach a point where the particles influence the slurry viscosity and require an impeller designed for slightly viscous mixing applications.

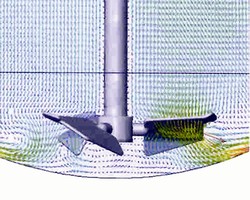

The MHS or High Solidity Hydrofoil impeller provides a wide blade hydrofoil design intended for medium viscosity or transitional-turbulent flow regime blending operations and high concentration solids suspension.

0 kommentar(er)

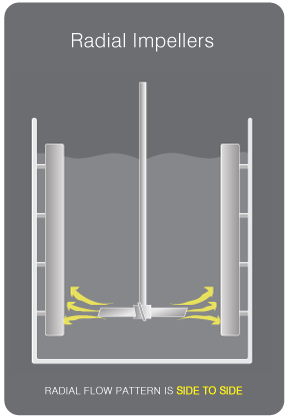

0 kommentar(er)